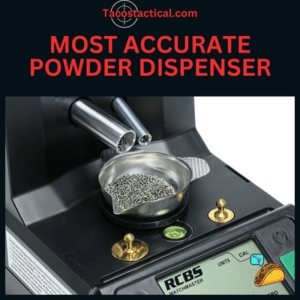

Powder dispensers are used to accurately measure and dispense powder for a variety of applications. Knowing which one is the most accurate can be a challenge for those in the market for one. We’ll take a look at what makes the most accurate powder dispenser so you can make an informed decision.

The accuracy of a powder dispenser depends on its ability to accurately measure out the desired amount of powder. Accurate measurement is essential, as too much or too little powder can lead to costly mistakes or wasted materials. That’s why it’s important to choose the right dispenser for your needs.

The key to finding the most accurate powder dispenser lies in understanding what features make it reliable and consistent. We’ll break down these features and explain why they’re important when it comes to selecting your ideal powder dispenser.

Table of Contents

Definition Of Powder Dispensers

A powder dispenser is an essential tool for any kitchen. It can be used to quickly and accurately measure out exact portions of powder, such as spices, flour, or sugar. It’s a must-have for anyone who wants to make sure their recipes are always perfect.

The right powder dispenser ensures that your ingredients will be measured accurately and evenly every time. This saves you time and money in the long run, as you don’t have to waste precious ingredients due to incorrect measurements. It also helps you create consistently delicious dishes with ease.

To get the most out of your powder dispenser, it’s important to find one that’s reliable and accurate. With the right model, you can rest assured that your measurements will be precise and consistent each time, no matter what type of ingredient you’re working with. This allows you to focus on creating delicious meals without worrying about whether or not your measurements are correct. With this in mind, let’s take a look at the different types of powder dispensers available today.

Different Types Of Dispensers

When it comes to powder dispensers, there are several different types available. The most common type is a manual dispenser, which involves measuring out ingredients by hand. With this type of dispenser, you can adjust the amount of powder being dispensed in a fairly precise manner. However, if accuracy is important to you, then an automated model may be the best choice. These models feature an accurate and adjustable digital scale that measures out ingredients in exact portions with minimal effort on your part.

For those who need even more precision when measuring ingredients, there are also commercial-grade powder dispensers available. These models tend to be much more expensive than manual or automated models but offer superior accuracy and greater control over the amount of powder being dispensed. They also tend to have higher-quality components that ensure long-term performance and reliability.

No matter what type of powder dispenser you choose, accuracy should always be your top priority. A quality model will provide consistent results every time so you can create delicious meals with confidence knowing that all your measurements are correct.

Features To Look For In A Quality Dispenser

To get the most out of a powder dispenser, there are certain features to look for. Firstly, accuracy is paramount; this means looking for a unit with an adjustable digital scale and a way to precisely measure ingredients. Additionally, you should seek out models that are well-constructed and feature high-quality components. This will help ensure your dispenser remains reliable and accurate over time.

Also, consider opting for a unit with a removable hopper or bowl; it makes cleaning up easier and also allows you to switch between multiple types of powders quickly and easily. Lastly, check if the dispenser has an automatic shut-off feature; this can help prevent overflows or spills so you don’t have to worry about wasting any ingredients.

By taking all these factors into account, you can find the best powder dispenser for all your culinary needs. With the right model, precision and accuracy are within reach – no matter what type of cooking or baking project you’re working on.

Benefits Of Automated Dispensing Systems

Switching to an automated dispensing system can bring a range of benefits for both home and professional cooks. From precise measurements to simplified clean-up, these systems can help simplify your culinary process. Here are just some of the advantages you can expect when choosing an automated dispenser:

- Increased Accuracy: Automated systems allow for more precise measurements than manual methods. With the ability to adjust digital scales, you can easily fine-tune your measurements to get the perfect amount each time.

- Faster Processing: Automated systems speed up the cooking or baking process by quickly and accurately calculating portions and ingredients; this means less time spent measuring and preparing, so you can get to eating or serving sooner!

- Easier Cleanup: Many models come with removable hoppers or bowls that make cleaning up much simpler than traditional methods. This helps save both time and energy after a long day in the kitchen.

These are just some of the advantages of upgrading to an automated dispensing system. With the right unit, you’ll be able to get consistent results every time – no matter what type of recipe you’re tackling.

How To Select The Right Dispenser

Choosing the right automated dispenser for your needs is an important decision. Here are some key considerations to keep in mind when making your selection:

- Accuracy: Different models will offer different levels of accuracy, so make sure you look for one that can meet your needs. Look for digital scales and adjustable settings to ensure a precise measurement each time.

- Capacity: Consider how much powder or ingredient you need to dispense at once and select a unit with the appropriate capacity. Some machines can even be programmed to dispense multiple ingredients at once, saving time and effort.

- Maintenance: Automated systems require regular cleaning and maintenance to stay in top shape. Make sure you choose one that’s easy to maintain – look for removable parts and simple instructions on how to clean, use, and store the machine.

By keeping these factors in mind, you can find the perfect automated dispenser for your kitchen needs. With the right system installed, you’ll be able to enjoy consistent results and more efficient cooking sessions.

Factors Impacting Accuracy

Accuracy is a crucial factor in the performance of any automated dispenser. From the smallest detail to the largest measurement, precision can make all the difference in ensuring an ideal result. Figuratively speaking, accuracy is like a tightrope walker – missteps along the way can lead to disastrous results. To ensure peak performance from your automated machine, there are several factors you should consider.

Temperature fluctuations can be particularly dangerous for powder dispensers as heat and cold can affect the density of the ingredients being dispensed. In addition, vibration caused by nearby equipment or traffic can throw off accuracy levels. To combat these issues, look for machines with temperature-regulated chambers and shock-absorbing materials to reduce movement during operation.

The design of your dispenser also plays a role in accuracy. Look for models with adjustable settings and digital scales that allow you to customize measurements according to your needs. By taking into account these three factors, you’ll be able to choose a machine that offers consistent results each time.

Now that you know what features are important when it comes to accuracy, it’s time to turn our attention to maintenance and troubleshooting tips – essential topics when selecting an automated powder dispenser that will last for years to come.

Maintenance And Troubleshooting Tips

It’s important to keep your powder dispenser well maintained in order to ensure accuracy and longevity. Regularly check for any signs of damage or wear and tear, as this could affect the accuracy of the machine. When cleaning your dispenser, use caution and make sure you follow the manufacturer’s instructions carefully. Always unplug the machine before beginning any maintenance or cleaning tasks.

Troubleshooting can be a time-consuming but necessary process if something goes wrong with your powder dispenser. If you encounter an issue, first review the user manual or contact customer service for assistance. If you can’t find a solution, it may be necessary to bring in a technician to take a look at the machine.

No matter how experienced you are with powder dispensers, it’s always better to be safe than sorry when it comes to maintenance and troubleshooting. Taking the time to assess issues ahead of time will save you time and money in the long run, so don’t skimp on quality when making repairs or upgrades.

Safety guidelines should always be followed when working with an automated powder dispenser.

Safety Guidelines

It’s important to remember that safety is paramount when dealing with a powder dispenser. Every year, there are thousands of incidents related to the misuse of automated machines, from minor injuries to more serious issues. To avoid any accidents, be sure to follow all safety guidelines provided by the manufacturer.

One interesting statistic is that in 2020 alone, over 3,500 people were injured due to incorrect use of powder dispensers in industrial and commercial settings. This highlights the importance of following safety protocols such as wearing protective clothing and ensuring the machine is properly grounded before use.

It’s also smart to keep an eye out for any potential risks when working with a powder dispenser. If something seems off or doesn’t feel right, it’s better to err on the side of caution and take appropriate measures to address the issue before continuing.

With these precautions in mind, we can move on to discuss cleaning and sanitizing techniques for powder dispensers.

Cleaning And Sanitizing Techniques

Keeping your powder dispenser clean and sanitary is key to ensuring it works properly. Regular maintenance and cleaning can help extend the life of the machine, as well as protect against any health risks associated with its use. Here are a few tips for keeping your powder dispenser in top condition:

- Thoroughly remove any powder residue from inside the machine after each use. This will help prevent clogs and other issues that can occur when particles build up over time.

- Detach all removable parts of the machine and clean them separately. Using a soft cloth or brush with mild detergent is usually sufficient to get rid of dirt or grime on these components.

- Sanitize all parts using a bleach solution or disinfectant spray after cleaning them. Make sure to let them dry completely before reassembling the machine.

Maintaining a regular cleaning routine is essential for keeping your powder dispenser working properly and safely. With proper care, you’ll be able to ensure that your machine performs optimally for years to come. From there, we can move onto cost considerations for purchasing a powder dispenser.

Cost Considerations

Finding the right powder dispenser for your needs can be a bit like navigating a minefield. With so many models and features to choose from, it’s easy to get overwhelmed by all the options. But with some careful consideration of cost, quality, and performance, you can find the perfect machine for your purposes.

When looking at price point, it’s important to remember that you get what you pay for. Cheaper models tend to have fewer features and may not last as long as more expensive ones. Likewise, more expensive machines are typically built with higher-quality materials and will perform better over time. As such, it’s best to aim for the mid-to-high range when shopping for a powder dispenser.

When searching for the most accurate powder dispenser on the market, look for models that are certified by an independent laboratory or testing agency. These machines have been tested rigorously and proven to dispense powders accurately at specified doses. Additionally, look for machines with adjustable speed settings so you can tailor them to your specific needs. With these criteria in mind, you’ll be sure to find a machine that meets your accuracy requirements and budget.

Frequently Asked Questions

How Often Should A Powder Dispenser Be Calibrated?

Calibrating a powder dispenser is no small task. It requires time, effort, and precision in order to get the most accurate results. But how often should a powder dispenser be calibrated? In order to make sure one’s measurements are as precise as possible, calibrating must be done regularly.

The frequency of calibration depends on several factors. If accuracy is critical, or if the powder being dispensed is highly sensitive, then calibration should be done more frequently. Incorrect measuring can lead to imprecise results which could potentially cause problems down the line. On the other hand, if accuracy is not so important and the powder isn’t very sensitive, then calibration may only need to be done every few months or so.

It’s important to remember that calibrating regularly will ensure that your powder dispenser works correctly and gives you the best possible results. Regular maintenance will also help extend the life of the machine and prevent costly repairs in the future. Not to mention it will give peace of mind knowing you have an accurate system in place for measuring your powders.

Does The Accuracy Of A Powder Dispenser Depend On The Type Of Powder?

The accuracy of a powder dispenser is a subject of much debate. Symbolic of the quest for precision, two distinct elements come into play: type and calibration. The former, type, poses the question: Does what is being dispensed affect how accurately it is done?

One answer to this inquiry is yes. Different types of powders have different levels of fineness, and therefore require different amounts of force to be dispensed properly. A coarse powder may require more force than a fine one; likewise, a wet powder may not disperse well with the same mechanism as one that is dry. It follows that each kind of powder needs its own special set-up in order to be dispensed accurately.

On the other hand, it could be argued that regardless of powder type, calibration alone can ensure accuracy. By adjusting settings and calibrating machines regularly, all kinds of powders can be dispensed with equal precision. In this case, it’s less about what’s being dispensed and more about how often the machine is calibrated – meaning that any kind of powder can be handled with ease if attention is paid to regular maintenance and check-ups.

So long as these two elements – type and calibration – are taken into account when using a powder dispenser, accuracy should not be an issue. Whether it’s simply calibrating or taking into account type differences, both are required for reliable results every time.

How Do I Know When A Powder Dispenser Needs To Be Replaced?

Knowing when to replace a powder dispenser is important. But how do you know? There are a few signs to look out for.

If the accuracy of your powder dispenser starts to decline, this might be an indication that it needs replacing. Also, if you start noticing a build-up of residue in your powder dispenser, or the device becomes clogged, it’s time to think about replacing it.

Lastly, if your powder dispenser has been in use for several years and is showing signs of wear and tear, then it may be time to replace it with a newer model. It pays to regularly check your powder dispenser’s accuracy and condition so you can get maximum performance from it.

Does The Size Of The Powder Dispenser Affect Its Accuracy?

At first glance, it would seem that the size of a powder dispenser wouldn’t affect its accuracy. But, upon further inspection, this couldn’t be more wrong. Surprisingly, the size of a powder dispenser can actually have a significant impact on its accuracy.

You may think that bigger powder dispensers would provide greater accuracy due to their increased capacity and storage spaces. However, larger sizes could potentially cause problems if they don’t fit in the prescribed area or space intended for them. This could lead to irregular measurements and inaccurate results when trying to dispense precise amounts of powder.

Conversely, smaller-sized powder dispensers are often able to fit into tight areas better than their large counterparts and therefore ensure more accurate results when doling out measured amounts of powder. Although they may not hold as much as large ones, their compactness allows for more precise measurements and superior accuracy in those measurements than what is possible with larger sized dispensers.

Thus, size does matter when it comes to choosing an accurate powder dispenser – you should always opt for one that is just the right size for your needs to ensure maximum precision in your measurements.

What Techniques Can Be Used To Test The Accuracy Of A Powder Dispenser?

Testing accuracy is essential when it comes to powder dispensers. It helps users identify the most reliable model and make sure they get their desired outcome. But how can they go about it? This article looks at techniques for testing the accuracy of a powder dispenser.

One way to test accuracy is by measuring the amount of powder deposited per dispensing cycle. This involves counting how many doses are dispensed, then measuring each dose with a weighing scale or volumetric device. If there’s any variation in the results, it could indicate an issue with the dispenser’s accuracy.

Another approach is to use a specialised test set-up that simulates actual usage conditions. This could involve setting up an apparatus that mimics a production line and running a few cycles through it. By comparing results from different machines, users can determine which one produces the most accurate output.

These tests will help users evaluate various models of powder dispensers and decide which one offers the best performance for their needs. They can also use this data to troubleshoot any existing issues or prevent future ones from occurring.

Conclusion

Accurate powder dispensing is essential for any production process. Using the wrong amount of powder can have disastrous results. To ensure accuracy, it’s important to understand how often a powder dispenser should be calibrated and replaced, what types of powders affect its accuracy, and how to test its accuracy.

Calibration should be done regularly according to manufacturer’s instructions. Different powders may require different calibration techniques so it’s important to research the best method for each type of powder used. Additionally, size can play a role in accuracy; larger dispensers often provide more accurate doses than smaller ones.

Testing the accuracy of a powder dispenser can also help ensure quality control. This can be done through manual testing or with automated tools such as scales or sensors. By taking the time to properly maintain and test your equipment, you can ‘sleep soundly’ knowing that your products will be consistently accurate and high-quality.

Founder of www.calisthenics-101.co.uk. Training calisthenics since 2012.

Currently working on: 30 second one-arm handstand, muscle-up 360, straddle planche.